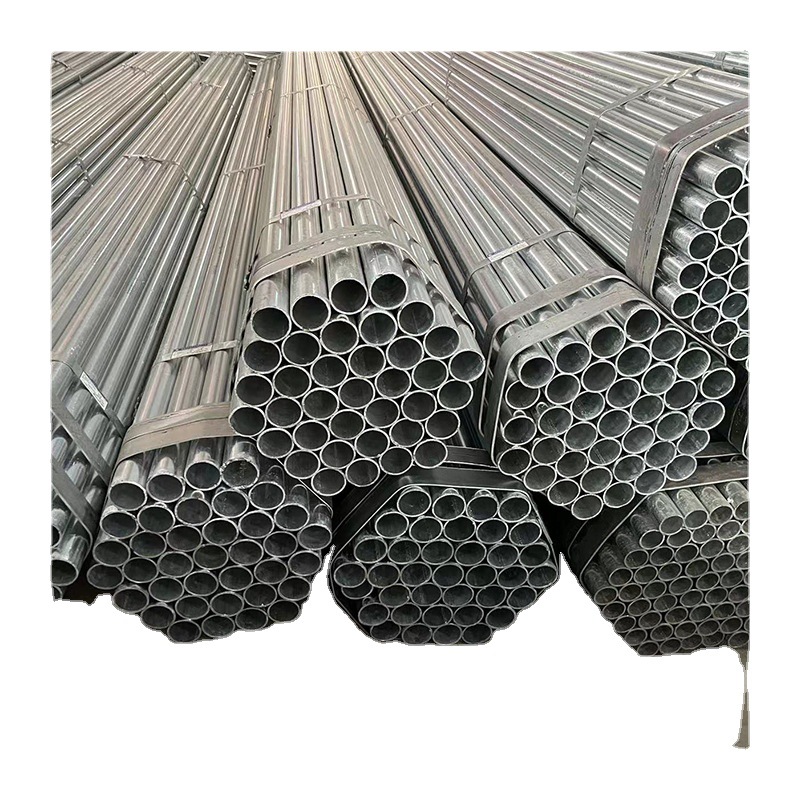

Seamless Steel Pipe is a steel pipe made by piercing solid billets or steel ingots and processing them through processes such as hot rolling, cold rolling, or cold drawing. Its core feature is that there are no welds and the overall structure is continuous and uniform.Seamless Steel Pipes are ideal for transporting fluids and gases under high pressure and temperature conditions, making them a preferred choice in industries such as oil and gas, construction, and manufacturing. Unlike welded pipes, our seamless pipes are produced without any joints or seams, which significantly reduces the risk of leaks and enhances their overall structural integrity.

Understanding Seamless Steel Pipe

Basic definition and characteristics

Seamless structure: made of perforated round steel with no welding marks on the surface, hence the name "seamless pipe".

High strength and pressure resistance: Due to the absence of weak points in welds, the pressure bearing capacity is superior to that of welded pipes, making it suitable for high-pressure, high-temperature, or corrosive environments.

Diverse materials: including carbon steel, alloy steel, stainless steel, etc., corrosion-resistant or high-strength materials can be selected according to needs.

Benefits of Seamless Steel pipe

Applications of Seamless Steel pipe

Seamless pipes are widely used in the following fields:

Fluid transportation: High pressure pipeline systems for oil, natural gas, chemical materials, and other materials.

Mechanical manufacturing: high-precision components such as bearings, hydraulic cylinders, and automotive transmission shafts.

Energy and Chemical Industry: High temperature and high pressure equipment such as boiler tubes, pressure vessels, and cracking tubes.

Special industries: aerospace structural components, geological drilling tools, etc.

Conclusion

Seamless pipes have become a key material in the industrial field due to their characteristics of no welds and high strength, especially suitable for high-pressure, high-precision, or corrosive environments.

Post time: May-12-2025